Product Catalogs

Need to know more about our solutions

- +971 6 5529570

- info@terra-t.com

- Hamriyah Free Zone/Phase II/ Plot 4P-03/ Sharjah / United Arab Emirates

Coating Removal Robots

General information about OFTEC Magnet Crawler

The magnet crawler is a compact vehicle for various industrial applications. It consists of a weight-optimised carrier construction containing two high torque drive units. Magnetic force is utilized to attach the crawler to metallic surfaces. The magnets used are protected against seawater and high attraction forces. Allowing movements along horizontal as well as vertical axes, the crawler design enables working with high recoil forces and hoses attached.

Crawler’s electric (optionally pneumatic) drives are controlled using a wireless remote system with infinitely variable speeds. Movement, rotation and speed of the system is managed by an operator from a secure location. Additional remotely switched channels allow the control of pumps, winches or other utility devices.

Applications: The crawlers are mainly used for cleaning and paint stripping of tanks and ships hull in combination with high-pressure water tools up to 3.000 bar. Optionally, waste or process water might be simultaneously collected with the removed material by a matching OFTEC suction system, thus maximally reducing discharge of pollutants into the environment.

If required, process water and removed material can be treated and separated with additional filter systems from OFTEC. Furthermore, it is possible to use the crawler system for other applications such as cutting, blasting as well as for inspection work with a camera.

Advantages: Due to the environmentally friendly process of coating removal, complete scaffolding of the object might be avoided. Subsequently elimination of time-consuming set-up period leads to faster project completion.

Since the crawler is driven remotely, low-fatigue work in combination with optimal work safety is guaranteed for the operator. Partial automation of the process makes it possible to use a higher pump capacity with greater recoil force generating maximum water pressure. Compared to manual gun operation magnet crawler deployment will result in increased area output performance.

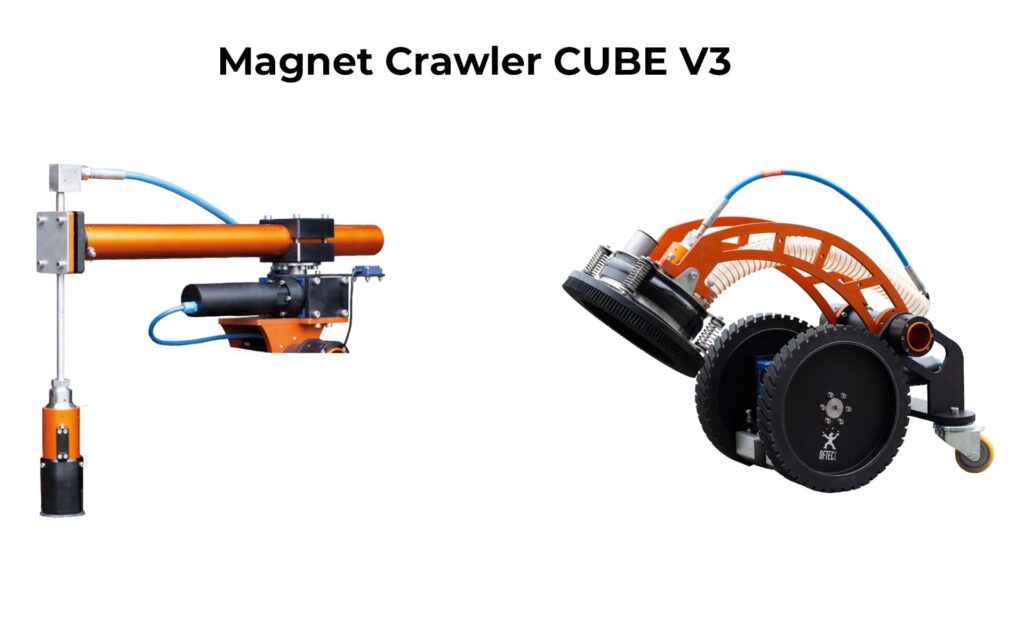

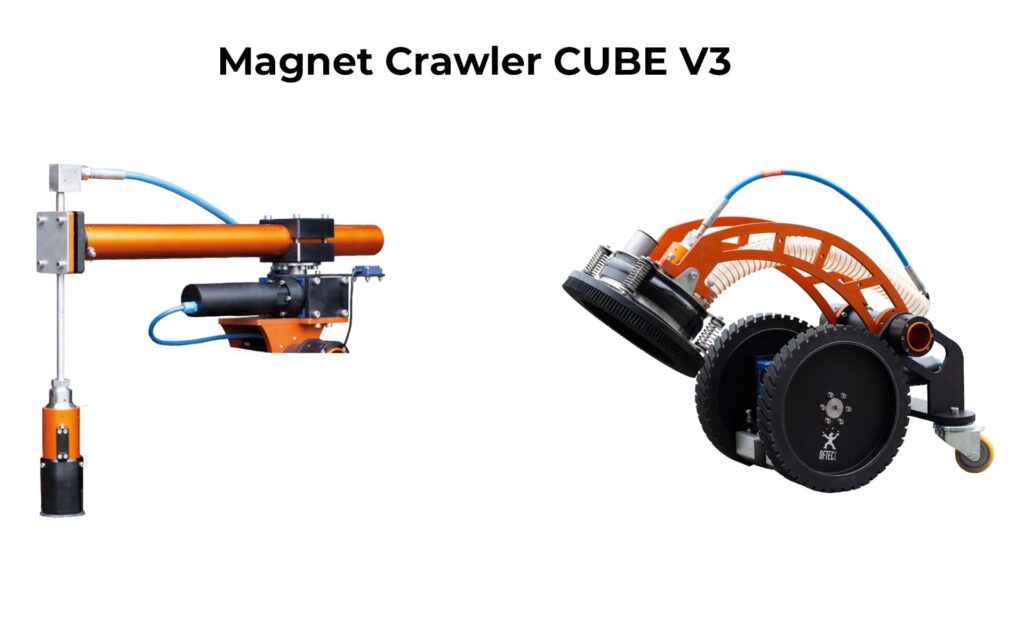

Magnet Crawler CUBE V3

The CUBE V3 magnetic crawler is designed to perform safe high-pressure water work on vertical, horizontal and overhead steel surfaces. Due to its high flexibility, a variety of jobs such as high-pressure washing and ultra-high-pressure work can be carried out semi-automatically. During the process, the waste water produced is easily extracted via the vacuum pot.

Due to its short wheelbase and compact dimensions, the Cube V3 is an agile vehicle. The additional magnets lead to high holding forces , so that it can also drive small curves without losing grip.

The CUBE V3’s multi-axis control allows the operator to adjust the distance between the water tool and the surface to be worked on during operation. In this way, it can easily overcome obstacles on the surface while maintaining an optimal distance from the surface at all times.

Due to the compact design and the quick-change system, the CUBE V3 can be dismantled quickly and easily. This feature makes it easy to transport the unit through a tank manhole, for example. Conversion to the CUBE S3 swing arm system is also possible due to the quick-change system.

ENVIRONMENTALLY FRIENDLY

Our robots offer significant advantages over traditional methods of surface preparation and industrial cleaning.

- Universal

- No need for scaffolding or cherry pickers

- Turns the work into a one-man job

- Safe, clean and efficient operation

- Closed systems available

- Low maintenance robots

- User-friendly

Ultra-high pressure blasting

- 3.000 bar – 30 l/min

- 2.500 bar – 45 l/min

- For removing paints and coatings

High-pressure water washing

- 1000 bar – 60 l/min

- For removing dirt, deposits and rust

Sandblasting

- Can be operated with all types of blasting media.

- For removing paints and coatings

- Holder for 2 sandblasting nozzles

Security

- Wireless control allows working from a safe distance

- No working on scaffolding or cherry pickers

- Safe and easy access to all horizontal, overhead and vertical surfaces

- Sensor technology ensures pump shuts off if contact with steel surface is lost

Cost-efficient

- 85% cost reduction

- Fewer working hours

- Less staff

- Up to 40m³

Productivity

- Up to five times faster than manual work

- Reduces operator fatigue

- 24/7 trouble free working

- Transforms work into a one-man job

- Six times more efficient than manual work

User-friendly

- Remote controlled system

- Fits through a manhole

- GPS and remote maintenance

Environmental impact

- Less water is used for the same work compared to manual work

Quality & Service

- 24/7 Full Service Package

- Consistent and high quality

- Own development and production

- Made in Germany

max. operating pressure | 3.000 bar |

max. flow rate | 30 l/min |

Working width nozzle bar | 170 mm |

Magnets | Permanent magnets, encapsulated in stainless steel |

Voltage drive motors | 36 V |

Weight crawler approx. | 68 kg |

Dimensions | 650 x 330 x 530 mm |

Control cable length) | 50 m (optional 50 m extra |

HD connection | M30x2 or M26x1.5 |

Control system | mobile control unit made of stainless steel |

Dimensions and weight | approx. 45 kg |

(L, W, H) | 1.200 x 600 x 600 mm |

IP protection class | IP 65 |

Connections CEE | 110 – 230 V |

Magnet Crawler CUBE S3

The CUBE S3 magnetic crawler is designed to perform safe high pressure water and sandblasting work on vertical, horizontal and overhead steel surfaces. Due to its high flexibility, a variety of jobs such as high-pressure washing, sandblasting and ultra-high pressure work can be carried out semi-automatically. Different water tools and sandblasting nozzles can be conveniently applied one after the other by using a quick-change system.

Due to its short wheelbase and compact dimensions, the Cube S3 is an agile vehicle. The additional magnets lead to high holding forces, hence it is able to operate small curves without losing grip.

The CUBE S3’s multi-axis control allows the operator not only to swivel the nozzles left and right, but also to adjust the distance of the water tool to the surface to be worked on during operation. In this way, it can easily overcome obstacles on the surface while maintaining the optimal distance to surface at all times.

Thanks to the compact design and the quick-change system, the CUBE S3 can be dismantled quickly and easily. This feature allows, for example, easy transport of the unit through a tank manhole. Conversion to the CUBE V3 vacuum system is also possible due to the quick-change system.

ENVIRONMENTALLY FRIENDLY

Our robots offer significant advantages over traditional methods of surface preparation and industrial cleaning.

- Universal

- No need for scaffolding or cherry pickers

- Turns the work into a one-man job

- Safe, clean and efficient operation

- Closed systems available

- Low maintenance robots

- User-friendly

Ultra-high pressure blasting

- 3.000 bar – 30 l/min

- 2.500 bar – 45 l/min

- For removing paints and coatings

High-pressure water washing

- 1000 bar – 60 l/min

- For removing dirt, deposits and rust

Sandblasting

- Can be operated with all types of blasting media.

- For removing paints and coatings

- Holder for 2 sandblasting nozzles

Security

- Wireless control allows working from a safe distance

- No working on scaffolding or cherry pickers

- Safe and easy access to all horizontal, overhead and vertical surfaces

- Sensor technology ensures pump shuts off if contact with steel surface is lost

Cost-efficient

- 85% cost reduction

- Fewer working hours

- Less staff

- Up to 40m³

Productivity

- Up to five times faster than manual work

- Reduces operator fatigue

- 24/7 trouble free working

- Transforms work into a one-man job

- Six times more efficient than manual work

User-friendly

- Remote controlled system

- Fits through a manhole

- GPS and remote maintenance

Environmental impact

- Less water is used for the same work compared to manual work

Quality & Service

- 24/7 Full Service Package

- Consistent and high quality

- Own development and production

- Made in Germany

max. operating pressure | 3.000 bar |

max. flow rate | 30 l/min |

Working width nozzle bar | 170 mm |

Magnets | Permanent magnets, encapsulated in stainless steel |

Voltage drive motors | 36 V |

Weight crawler approx. | 68 kg |

Dimensions | 650 x 330 x 530 mm |

Control cable length) | 50 m (optional 50 m extra |

HD connection | M30x2 or M26x1.5 |

Control system | mobile control unit made of stainless steel |

Dimensions and weight | approx. 45 kg |

(L, W, H) | 1.200 x 600 x 600 mm |

IP protection class | IP 65 |

Connections CEE | 110 – 230 V |

The VacuMag 3000 was developed for safe high-pressure water work on vertical, horizontal and overhead steel surfaces. All process and waste water is extracted with assistance of a vacuum system.

The built-in self-rotating rotary union DDF 160-MB 3000 contains an adjustable magnetic brake,

hence optimum speed can be set easily and quickly from outside (optionally adjustable via remote control). Vacuum pot containing solid nozzle arm with a special nozzle arrangement for efficient coating removal.

EASIER, SAFER AND MORE ENVIRONMENTALLY FRIENDLY

Robots offer significant advantages over traditional methods of surface preparation and industrial cleaning:

- Universal applications

- No need for scaffolding or cherry pickers

- Turns the work into a one-persons job

- Safe, clean and efficient procedure

- Closed loop process water systems available

- Low maintenance robotic technology

- User-friendly operation

Ultra-high pressure blasting

Max. 3.000 bar – 30 l/min

Max. 2.500 bar – 45 l/min

For removing paints and coatings

High-pressure water washing

Max. 1000 bar – 60 l/min

For removing dirt, deposits and rust

Security

- Wireless control allows working from a safe distance

- No working on scaffolding or cherry pickers

- Safe and easy access to all horizontal, overhead and vertical surfaces

- Sensor technology ensures pump shuts off if contact with steel surface is lost

Cost-efficient

- 85% cost reduction

- Fewer working hours

- Less staff

- Up to 40m³

Productivity

- Up to five times faster than manual work

- Reduces operator fatigue

- 24/7 trouble free working

- Transforms work into a one-man job

- Six times more efficient than manual work

User-friendly

- Remote controlled system

- Fits through a manhole

- GPS and remote maintenance

Environmental impact

- Less water is used for the same work compared to manual work

Quality & Service

- 24/7 Full Service Package

- Consistent and high quality

- Own development and production

- Made in Germany

max. operating pressure | 3.000 bar |

max. flow rate | 45 l/min |

Magnets | Permanent magnets, encapsulated in stainless steel |

Voltage drive motors | 36 V |

Weight crawler approx. | 96 kg |

Control cable length | 50 m (50 m extension optionally) |

HD connection | M30x2 or M26x1.5 |

Control system | mobile control unit made of stainless steel |

Dimensions and weight | approx. 45 kg |

(L, W, H) | 1,200 x 600 x 600 mm |

IP protection class | IP 65 |

Connections CEE | 110 – 230 V |

Magnet Crawler UniMag 3000

The UniMag 3000 was developed for safe high-pressure water and sandblasting work on vertical, horizontal and overhead steel surfaces. Due to its high flexibility, a variety of jobs can be carried out, such as high-pressure washing, sandblasting and ultra-high-pressure work, where different water tools and sandblasting nozzles can be conveniently used via a quick-change system.

EASIER, SAFER AND MORE ENVIRONMENTALLY FRIENDLY

Robots offer significant advantages over traditional methods of surface preparation and industrial cleaning:

- Universal applications

- No need for scaffolding or cherry pickers

- Turns the work into a one-persons job

- Safe, clean and efficient procedure

- Closed loop process water systems available

- Low maintenance robotic technology

- User-friendly operation

Ultra-high pressure blasting

- 3.000 bar – 30 l/min

- 2.500 bar – 45 l/min

- For removing paints and coatings

High-pressure water washing

- 1000 bar – 60 l/min

- For removing dirt, deposits and rust

Sandblasting

- Can be operated with all types of blasting media.

- For removing paints and coatings

- Holder for 2 sandblasting nozzles

Security

- Wireless control allows working from a safe distance

- No working on scaffolding or cherry pickers

- Safe and easy access to all horizontal, overhead and vertical surfaces

- Sensor technology ensures pump shuts off if contact with steel surface is lost

Cost-efficient

- 85% cost reduction

- Fewer working hours

- Less staff

- Up to 40m³ coating removal per hour

Productivity

- Up to five times faster than manual work

- Reduces operator fatigue

- 24/7 trouble free working

- Transforms work into a one-man job

- Six times more efficient than manual work

User-friendly

- Remote controlled system

- Fits through a manhole

- GPS and remote maintenance

Environmental impact

- Less water is used for the same work compared to manual work

Quality & Service

- 24/7 Full Service Package

- Consistent and high quality

- Own development and production

- Made in Germany

max. operating pressure | 3.000 bar |

max. flow rate | 30 l/min |

Working width nozzle bar | 170 mm |

Swing arm range | 1500 mm |

Magnets | Permanent magnets, encapsulated in stainless steel |

Voltage drive motors | 36 V |

Weight crawler approx. | 72 kg |

Dimensions | 700 x 680 x 580 mm |

Control cable length | 50 m (50 m extention optionally) |

HD connection | M30x2 or M26x1.5 |

Control system | mobile control unit made of stainless steel |

Dimensions and weight | approx. 45 kg |

(L, W, H) | 1.200 x 600 x 600 mm |

IP protection class | IP 65 |

Connections CEE | 110 – 230 V |